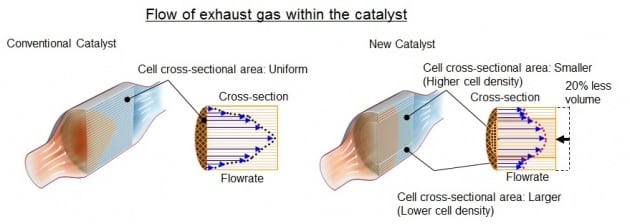

Toyota has introduced a new exhaust purifying catalyst that is smaller (approximately 20% less volume), and uses 20% less precious metal compared to conven

Toyota has introduced a new exhaust purifying catalyst that is smaller (approximately 20% less volume), and uses 20% less precious metal compared to conventional catalysts. The new technology will gradually make its way into new vehicle models, beginning with the Lexus LC 500h later this year.

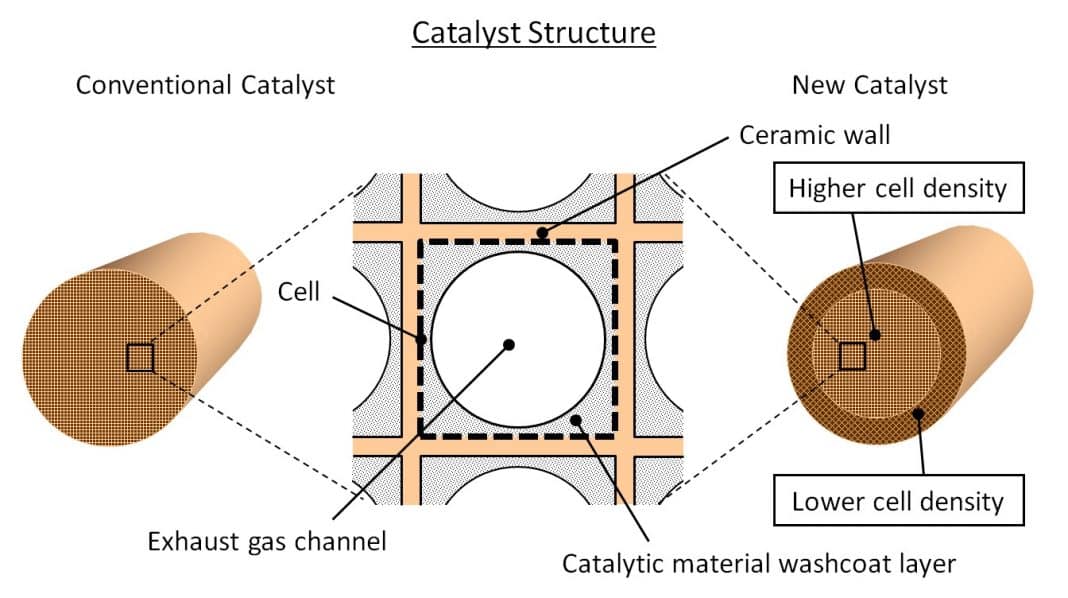

The catalyst features the world’s first integrally-moulded Flow Adjustable Design Cell (FLAD) substrate, which has a different cell cross-sectional area at the inner portion compared to that at the outer portion.

The new FLAD substrate (developed by Toyota together with Denso) improves the uniformity of exhaust gas flow, allowing for the same exhaust gas purification performance as that of conventional catalysts while requiring less precious metal.

As the diagrams show, the newly developed FLAD substrate doesn’t result in an unbalanced flow of exhaust gas as compared to a conventional catalyst, where the flow of gas through the inner portion of the catalyst is faster, and at a higher volume than that through the outer portion.

Therefore, the FLAD substrate catalyst doesn’t require more precious metal at the inner portion of the catalyst, where the flowrate is greater, in order to maintain purification performance. The walls of cells within both substrates are washcoated with catalytic materials, like platinum (Pt), rhodium (Rh), palladium (Pd) and other precious metals.

This provides a catalytic effect, where harmful gases such as carbon monoxide (CO), unburned hydrocarbons and nitrogen oxide (NOx) are purified within the exhaust via oxidation-reduction